HAAS Filtertechnik

for painting booths and spray walls

Users benefit from a environmentally friendly and

cost-saving Overspray separation system.

In recent years, the company Haas Kunststofftechnik has developed a hybrid system for Overspray arrestors in paint booths and spray walls.

The system consists of three components: the pre-separator consisting of plastic lamellas, the downstream filter cassettes and a collecting tray. Due to its sustainability, the system impresses both with its ease of maintenance and its very low operating costs.

Sustainability/strong>

through reusable separator lamellas

Reduction of operating costs

up to 60 % by cleaning the plastic lamellas and saving energy and water costs

Paint recovery

for draining off paints and coatings

Customized retrofitting

for existing plants

Individual installation

The installation can be horizontal as well as vertical.

Modification

from wet washing to dry separation

Waste volume is reduced to a minimum, the only waste to be disposed of is paint residue.

No hazardous waste

of paint sludge

Cleaning without additives

The plastic lamellas are dry-cleaned, without the addition of water and chemicals.

Description or areas of application

The compact modules of the hybrid system can be mounted horizontally or vertically in any number as a closed exhaust wall, also below the painting zone, and are suitable for use in new and existing plants. Due to their design and ease of use, they offer several advantages. For example, the reusable separator lamellas reduce running costs.

Since the HAAS-lamella separator works without water, chemicals or other additives, the service life of the lamellas is several years depending on the type of paint. In the case of the filter cassettes, the simply designed fastening system allows them to be changed in just a few minutes.

Prior assembly is not necessary. The hybrid system is suitable for plants of different sizes, where a simple system is required and can be used in the industrial sector, in the automotive industry or by automotive suppliers for manual painting plants up to robot painting.

Overspray flows through lamella labyrinth

The overspray is separated as it flows through the semi-tubular separator lamellas, which are arranged like a labyrinth.

In the process, most of the paint particles adhere to the separator lamellas and build up into larger paint layers.

The remaining overspray is absorbed by the filters behind it. They are located in cassettes that can be equipped with different fine filter mats depending on the type of paint.

The mats themselves can easily be replaced on the back or front of the module.

Uniform overspray loading of the front and rear lamella rows

After cleaning the separator lamellas, only approx. 275 kg of pure paint residues need to be disposed of.

Different types of paint

Paintings that still have a certain amount of residual moisture during a paint process will deposit most of the solid particles on the lamellas. Layer thicknesses of up to a few centimeters build up, so that an absorption capacity at the separator lamellas of approx. 32 kg/m² overspray is achieved.

The remaining overspray is retained in the filter mats behind it.

The lamellas are cleaned outside the plant. For this purpose, they are dismantled using a cordless screwdriver with an attachment and can be cleaned by the cleaning staff with simple tools.

Draining off paints

Paints and coatings that drain off and that only cure in connection with post-treatment or that cure slowly, accumulate to a thickness on the separator lamellas and then drains off downwards.

This creates a regenerating effect and the lamellas can remain in use for several weeks.

The overspray that drains off is collected in separate collection trays and, depending on the type of paint, reused or disposed of as pure paint residue.

When cleaning the separator lamellas with high residual moisture, the overspray can be removed from the lamellas in a film-like manner and disposed of according to type.

Draining off coatings are collected in separate trays for recovery.

Draining off paint collected in separate tubs

Approx. 200 kg of pure paint residues which can be given for disposal

Paints with residual moisture can be removed from the lamella very easily.

Overspray which can be peeled off like a film

VERTICAL INSTALLATION EXAMPLES

HORIZONTAL INSTALLATION EXAMPLES

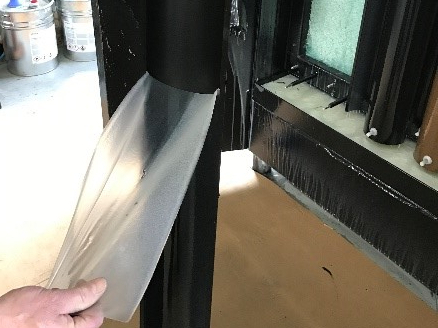

A conversion of a 25 m² floor extraction from cardboard filter to an HAAS-lamella separator

A retrofitting of a 20 m² floor extraction system with wet separation to an HFT lamella separator. Custom-made separator modules.

The extraction surface is easily accessible via a grating, so that the filter fleece and separator lamellas can be conveniently installed.

The pre-separation of the HAAS-lamellas works very well in the horizontal installation, as only small residual particles of overspray can be detected in the fine filter.

Your advantages with the HAAS-lamella separator

Payback in just a few months and

possible operating cost savings of up to 60 %

Your advantages with the HAAS-lamella separator

Payback in just a few months and possible operating cost savings of up to 60 %

Filter change in a few minutes due to the simple fastening system

No need to prepare the components when changing filters, such as the assembly of cardboard boxes

Sustainability

thanks to reusable separator lamellas that can be used for several years

Quick and easy retrofitting for existing plants

Waste volume is reduced to a minimum, only pure paint residues have to be disposed of

Anwenderbericht:

Großer Schritt für den Umweltschutz

Das rheinland-pfälzische Unternehmen Haas Kunststofftechnik hat ein innovatives System zur Nasslackabscheidung entwickelt. Das Hybridsystem verringert die laufenden Kosten durch wiederverwendbare Abscheiderlamellen, leicht austauschbare Feinfilter und reduziertes Abfallvolumen, so der Hersteller. BESSERLACKIEREN hat jetzt Anwender nach ihren Erfahrungen gefragt.

Einsatz bei allen Lackierprozessen Zu ihnen gehört die im bayerischen Regensburg ansässige Maschinenfabrik Reinhausen (MR). MR-Produkte regeln 50% des weltweit erzeugten Stroms. Laut Markus Wendler, bei MR in der Arbeitsvorbereitung/Assembly Engineering, zuständig für Oberflächenbeschichtung-/lackierung und den daraus resultierenden Korrosionsschutz, werden die Stufenschalter zur Regelung von den Hochspannungstransformatoren selbst lackiert: „Das Nasslackabscheidesystem kommt bei all unseren Lackierprozessen bzw. -anlagen zum Einsatz.

Die Bauteile werden mit einer so genannten ‚Power-‘ und ‚Free-Kette‘ durch die Lackieranlage und die dazugehörigen Vorbehandlungskammern getaktet. Wir lackieren manuell und je nach Korrosivitätskategorie bis hin zu Offshore in mehreren unterschiedlichen Durchläufen.“ Bis 2018 wurde der Overspray über ein Nasslackabscheidesystem, Koagulierung mittels Chemieeinsatz und Flottierung gebunden, ausgetragen und entsorgt. Mit Umstellung auf das Trockenlackabscheidesystem werden nun die Lackreste trocken ohne Chemiezusatz beseitigt. Es müssen...

The system received the Environmental Leadership Award 2015 from the Daimler AG

On October 13, 2015, the innovative dry separation system for spray paints received Daimler’s 2015 Environmental Leadership Award for environmental protection in Stuttgart. The environmental award ELA (Environmental Leadership Award), which is awarded internally at Daimler, is presented every two years.

What our customers say about us:

Conversion from wet separation to the HAAS-lamella separator

As can be seen from the TÜV measurement results, the residual dust values are from 0.2 mg/Nm3 to 0.6 mg/Nm3 and are thus well below the promised or legally prescribed limit value of 3 mg/Nm3.

With the retrofitting of the paint plant, there is no longer any hazardous waste from paint sludge, and around 18.000 kWh of electrical energy and 4.000 m3 of water are saved annually.

The HAAS-lamella separator works very well in our plant.

Conversion of cardboard filters to the HAAS-lamella separators

The conversion of our paint plant from cardboard filters to the HFT lamella separator system, which has now been in use for 7 years, has resulted in enormous cost savings of 69 %.

Regenerable plant

When using the HAAS-separator lamellas in our coating plant, the overspray is optimally separated and drains off on the plastic lamellas, resulting in a regenerable effect and the lamellas can remain in use for several weeks. Up to 95 % of the overspray that drains off is collected in separate collecting trays and used for reprocessing.

Statement on – Changing the lamellas and filter fleece

Today we changed separator lamellas and filter fleece on a 7 m² plant.

With the help of the supplied screw attachment, the lamellas could be removed very easily. The filter fleece was also very easy to remove.

After cleaning the frame and the surrounding area, new filter fleece and lamellas were installed in a time of approx. 20 minutes with two employees.

According to the customer, the switch was very easy.

Standort

HAAS Kunststofftechnik GmbH & Co. KG

Am Wolfsgestell 22

D-56477 Rennerod

Kontakt

Tel.: +49 (0) 2664 4 67 37-0

Fax: +49 (0) 2664 - 911 248

Mail: info[at]haas-kunststofftechnik.de